Trim Solutions

Fallbeispiel Cadillac ATS

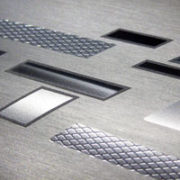

One Carrier for Three Authentic Materials

Process

Omni-Bond Aluminum

Brushed Aluminum

Screen Printed Aluminum

Challenge

Utilize a common carrier for three unique substrates.

Application

Cadillac ATS interior trim

Solution

Engineers and designers at GM, Lawrence Automotive and Northern Engraving collaborated on this program to realize the end goal of utilizing a common carrier for real wood, carbon fiber and aluminum trim saving up-front costs on injection mold tooling. Three unique materials offer three distinct looks for the customization of the Cadillac ATS. Design criteria for each of the substrates were taken into consideration early on to optimize part designs for the engineering of common carriers. Standardizing material thicknesses was essential to the success of the program and creating a seamless look within the vehicle.

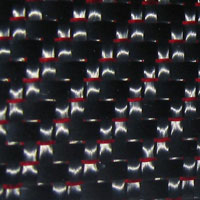

Design intent for the decorative aluminum trim plate was to create an intricate layered look conveying precision and sports luxury. Embossed and debossed details were considered along with diamond cutting. The final design builds on this intent with an alternative approach which integrates layers of processes combined with mechanical finishes to create the in-laid metal design. Depth and dimension were achieved without the need to add embossed or diamond cut details. The aluminum trim showcases decorative aluminum processes creating an eye-catching option for interior trim.